Lupine Publishers Group

Lupine Publishers

Menu

ISSN: 2637-4595

Review Article(ISSN: 2637-4595)

Jute-Old World Fiber to New World Fashion Volume 2 - Issue 5

Ashok Athalye*

- Department of Colours Business, Atul Colors, Valsad, India

Received: August 30, 2018; Published: September 07, 2018

*Corresponding author: Ashok Athalye, Department of Colours Business, Atul Colors, Valsad, India

DOI: 10.32474/LTTFD.2018.02.000147

Abstract

Jute is a natural vegetable fiber, abundantly cultivated in the Indian subcontinent. Owing to its inherent color composition it was known as the golden fiber of the old world and traditionally used in non-textile applications like agricultural bulk packaging. With the technological advancements in fiber processing and the end use designing, it is gaining popularity in the global fashion trend.

Keywords: Jute; Vat Dyes; Home Furnishing; Decorative Textiles

Introduction

Jute is a cellulosic fiber produced from the stem of a plant called genus Corchorus and owing to its yellowish brown shiny appearance is popularly known as the Golden Fiber. It is extensively used in agricultural bulk packaging due to its inherent tensile strength, low extensibility, moderate moisture retention and better breathability. The Jute plant is known to originate from the Indian subcontinent which provides favorable warm and wet monsoon climatic conditions for its cultivation. India and Bangladesh account for almost 95% of global Jute production especially due to the cultivation in the area called as Ganges delta. Jute plants are easy to grow, cheap to cultivate and have a high yield per acre.

For centuries, Jute was an integral part of greater India known as the old world and reportedly used during the bronze age and later was one of the most widely sourced products by the Western Europe and Northern America. Among the natural fibers it occupies place next to cotton in the amount produced and the variety of uses.

Properties of Jute

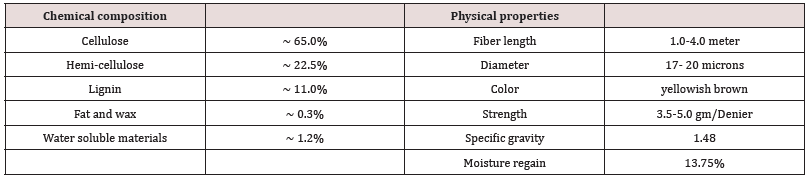

The chemical composition and the physical properties of Jute are furnished in the Table 1.

Though, Jute is basically a natural cellulosic fiber, it has many distinct characteristic features and advantages over cotton, as listed below

a) Sustainable, bio-degradable and recyclable.

b) Needs least pesticide and fertilizer.

c) Possesses natural golden hue and silky soft feel.

d) Economically produced vegetable fiber.

e) Versatile usage from packaging, textiles, construction and agricultural sectors.

f) Good insulating and antistatic properties.

g) Good thermal conductivity and a moderate moisture regain.

h) Good acoustic insulating properties.

i) Ease of blending with other natural as well as synthetic fibers.

j) Comfort wear properties as does not cause skin irritations.

k) Easy to color with wide range of dye class.

Jute cultivation helps reduce carbon footprint. It is estimated that a hectare of Jute plant consumes about 15 MT of carbon dioxide and releases about 11 MT of oxygen. The plant grows to an average of 10 to 12 feet in height and the fiber is obtained from the inner bast tissues of its stem. It needs careful processing parameters to retain desired fiber characteristics and avoid undue damage.

Processing of Jute

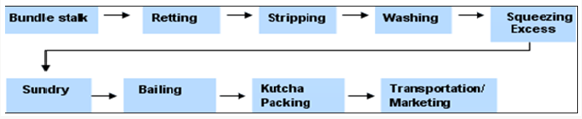

Fibers of jute lie beneath the bark of the plant surrounding the central part of the stem. The fibers are extracted from the plant through the following process:

The process of separating and extracting fibers, which are glued together by natural plant pectinase is called retting and traditionally involves submerging stems in water for 10–30 days. After Retting, the non-fibrous matter is removed by manual scrapping or by mechanical beating. The fibers are then dipped in tamarind water for 15 to 20 minutes to remove its dark color. Then it is washed in clean water again. The washed fibers are hung in bamboo railings for 2 to 3days. The washed and dried fibers are then processed using eco-friendly batching oil | lubricant and suitable enzymes to remove the non-fibrous material. Subsequently, it is passed through carding machines to make it finer, softer and cleaner in appearance. The fuzz, small fiber ends projected from the surface of yarn is removed by enzymatic bio-polishing to improve handle and appearance. Finally, the dried fibers are graded as top, middle and bottom and then packed in kutcha bales for transportation and marketing (Figure 1).

Coloration of Jute

The aesthetic appeal of Jute is enhanced by its adequate coloration. All classes of dyes suitable for dyeing cellulosic substrates like cotton are applicable for dyeing of Jute. Moreover, owing to the presence of the non-cellulosic constituents, Jute can also be dyed with dyes like acid, metal complex and basic. Industrially, the most commonly used dyes are Direct, Reactive, Vat and Sulphur. They produce variety of shades depending on the end use requirements. Dyeing is carried out mainly by jigger dyeing and padding methods. After-treatment of dyed Jute fabric produces optimum fastness characteristics. The performance of major dye classes is summarized below:

a) Direct dyes

i. Simple dyeing process

ii. Economical cost of dyeing

iii. Of application

iv. Least effluent load

v. moderate wash fastness with moderate to high light fastness

b) Reactive dyes

i. Simple dyeing process

ii. Moderate cost

iii. Bright shades

iv. Good wash fastness with moderate to high light fastness

c) Vat dyes

i. Complex dyeing process

ii. Comparatively expensive

high wash fastness and light fastness

d) Sulphur dyes

i. Slightly complex dyeing process.

ii. Low cost.

iii. Moderate wash fastness and light fastness.

iv. Dull shades, limited shade gamut.

Among all classes of dyes, dyeing of Jute with TULADIR Direct dyes is very popular and commonly practiced in industry due to better exhaustion, simple dyeing method and good depth of shades. However, nowadays Jute dyeing with NOVATIC Vat dyes is gaining popularity owing to their superior fastness properties (Figure 2).

The special features and associated benefits of such dyes are as follows:

a) Wide shade gamut

b) High tinctorial strength

c) Low electrolyte consumption

d) Excellent build-up

e) High exhaustion profile

f) Excellent lab and bulk reproducibility

g) Easy wash-off

h) Good level dyeing performance.

Uses of Jute

Traditionally, Jute was used in non-textile applications like packaging materials in bags, sacks, twines and ropes. However, based on its inherent sustainable properties, it is gaining importance and is being used in a number of values added and diversified applications. Recently the usage of Jute has grown in apparel clothing, home textile as well technical textiles (Figure 3).

The demand for Jute is increasing due to its techno-commercial cost competitiveness as well as eco-friendly biodegradable characteristics. The various end use applications of Jute involve.

a) Apparel wear - the luster, softness and uniformity of this fiber make it ideal for production of comfort wear clothes, particularly pullovers and intimates.

b) Home textiles - this fiber is traditionally used for floor covering mats, curtains, chair coverings and carpets.

c) Industrial | Technical - owing to its long length and tensile strength, Jute is widely used in making rope and twines for industrial use and making baskets and bags for storing grains and agricultural products.

d) Other - used as herb and food in cooking of soups in some Middle Eastern and African countries.

In India, the Golden fiber-Jute, is one of the most important cash crops of great socio-economic importance. There are about 80 Jute processing mills, concentrated mostly in the eastern part, which support lives of around 4.0mn workforce involved from farm to fiber production. The Indian Jute industry has been expanding and offering wide range of life style consumer products which makes India the largest consumer of jute in the world. The US is the biggest market for Indian Jute based products followed by UK, Germany, Italy and Spain which contributes exports of about Rs. 1000cr for the Indian economy.

The usage of Jute has expanded beyond the traditional applications and Jute is being used in various value added textile segments. Diversified Jute products consist of high performance technical textiles, geo-textiles, composites, etc. Its strength, durability, UV protection, sound and heat insulation, low thermal conduction and anti-static properties make it a wise choice in home décor. Jute fibers are carbon-dioxide neutral and naturally decomposable. The Jute fabric is used for soil erosion control, seed protection, weed control, and many more agricultural and landscape applications. Textiles made out of Jute are also used in camouflage articles as it resembles and naturally blends with surrounding grass or brush. Diversified by-products from Jute find use in cosmetics, medicine, paints and other products. Jute sticks are used as fuel and fencing materials [1-3].

Jute fibers are widely used as self or in blends with other natural | synthetic fibers for making industrial twines and rope. Various other uses of Jute involve manufacturing of carpet backing cloth and canvas. Jute cloths are used for making eco-friendly packaging, wrappers, wall coverings and home furnishing upholstery. These are good substitute for forest wood and bamboo for production of particle boards, pulp and paper. Diversified jute products like espadrilles (casual shoes | footwear), fashion bags and jewelry and floor coverings are becoming popular and more and more valuable to the consumers (Figure 4).

Summary

With the increasing global awareness towards the use of sustainable, bio-degradable and eco-friendly products, Jute is progressively regaining and widening its usage in both the traditional and diversified applications. So, modification of feel and look have become essential depending on the end use requirement resulting in increasing the demand for bright, wash fast and light fast dyed Jute substrates. The demand of Jute articles, viz. wall hangings, mats, decorative handicrafts, shopping bags, soft luggage, wall cover, dividers, carpets, upholstery fabric are increasing day by day. The sense of awareness among the consumers is certainly remarkable and the producer’s ability to translate, innovate and create has developed opportunities for profiting from the growing consumer demand. Specialty dye and chemicals are tailor-made solutions to satisfy overall demands of Jute processors for value added products. Thus, the golden fiber hitherto remained confined to making of low quality sacks and ropes in the old world has come into the limelight and caught fancy of the global fashion designers in their quest for a sustainable eco-friendly fiber and has become a new world fashion.

References

Top Editors

-

Mark E Smith

Bio chemistry

University of Texas Medical Branch, USA -

Lawrence A Presley

Department of Criminal Justice

Liberty University, USA -

Thomas W Miller

Department of Psychiatry

University of Kentucky, USA -

Gjumrakch Aliev

Department of Medicine

Gally International Biomedical Research & Consulting LLC, USA -

Christopher Bryant

Department of Urbanisation and Agricultural

Montreal university, USA -

Robert William Frare

Oral & Maxillofacial Pathology

New York University, USA -

Rudolph Modesto Navari

Gastroenterology and Hepatology

University of Alabama, UK -

Andrew Hague

Department of Medicine

Universities of Bradford, UK -

George Gregory Buttigieg

Maltese College of Obstetrics and Gynaecology, Europe -

Chen-Hsiung Yeh

Oncology

Circulogene Theranostics, England -

.png)

Emilio Bucio-Carrillo

Radiation Chemistry

National University of Mexico, USA -

.jpg)

Casey J Grenier

Analytical Chemistry

Wentworth Institute of Technology, USA -

Hany Atalah

Minimally Invasive Surgery

Mercer University school of Medicine, USA -

Abu-Hussein Muhamad

Pediatric Dentistry

University of Athens , Greece

The annual scholar awards from Lupine Publishers honor a selected number Read More...