Lupine Publishers Group

Lupine Publishers

Menu

ISSN: 2643-6736

Research Article(ISSN: 2643-6736)

Performance comparison of two roselle drying systems Volume 4 - Issue 2

Federico Hahn1*, Mónica Berrocal Aguilar2, Netzahualcóyotl Flores Lázaro3 and Deysi Gómez Maldonado4

- 1Irrigation Department, Universidad Autonoma Chapingo, Texcoco, México

- 2IAUIA, Universidad Autonoma Chapingo, Texcoco, México

- 3Ambient Education Department, Universidad Indigena de Michoacán, Pátzcuaro, México.

- 4Agroindustry Department, Universidad Autonoma Chapingo, Texcoco, Mexico.

Received:December 09, 2023; Published:December 13, 2023

Corresponding author:Federico Hahn, Irrigation Department, Universidad Autonoma Chapingo, Texcoco, México

DOI: 10.32474/ARME.2023.04.000185

Abstract

Agro-systems that avoid food decay and spoilage are required to extend produce shelf life. Driers remove food internal water, so dehydrated calyces can be stored without refrigeration for years. A roselle flower dehydrator with forced convection and air recirculation was tested in a high relative humidity environment. The constant circulation of dry hot air helped to maintain the air relative humidity below 28%. The equipment-controlled temperature at 55°C and dried calices in 7 hours. As several trays were used final calyx moisture homogeneity was analyzed and differences up to 2% obtained. After two years, stored calyces remained fungal-free and with excellent flavor. Solar indirect driers took 25 hours to dehydrate calices, as air temperature was not constant, and air relative humidity was always above 60%. Calyces’ moisture homogeneity could increase up to 4.5% being higher at the drier’s contours.

Keywords:Tray drier; drying homogeneity; solar drier; air recirculation

Introduction

The world’s population is growing daily so food production must increase to feed its people. The Food and Agriculture Organization (FAO) reported in 2020, that one‐third of the produced food (1.3 billion tonnes) is lost every year [1]. In Mexico up to 45% of tropical fruit is lost after maturation due to poor post-harvest treatments being higher than the 30-40% values reported in developing countries [2]. Drying is a popular food preservation technique used in developing countries, extending agricultural produce shelf life, and decreasing storage of fresh fruit and vegetables [3]. In the drying process moisture is removed from the food produced, preventing the growth of micro-organisms and food decay. Dry products preserve the nutritional value, color, and flavor important during produce retail operation. There are several types of driers based on the energy used and in the way in which air flows. In many countries, the lack of electricity in rural areas has brought the solar drying revolution [4-6]. Solar driers are classified as direct, indirect, or hybrid depending on how heat is transferred to the food [7]. Direct cabinet solar driers expose the product to solar radiation, but it is time consuming and as environmental variables are not controlled, nutrient properties can be lost [8]. Indirect solar driers present a drying chamber and a solar air heater, decreasing drying time by 40% [9-10]. Commercial driers require to process the raw product during day and night, so hybrid driers are used [11]. Several other energy combinations include electricity, gas, and biomass stoves [12]. Hybrid greenhouse solar driers use a thermal exchanger together with evacuated tube collectors to accomplish a better drying performance [13]. Hot air convective driers are commonly used for high food production systems. Air recirculation systems can be temperature controlled with accuracy, obtaining energy saving up to 70% [14]. These systems consist of a drying chamber where hot-dry air is recirculated continuously with a fan and several trays [15]. Nevertheless, airflow distribution over the trays is uneven and provides non-heterogeneous slice drying [16]. Roselle producers requires a versatile prototype that can dry calyces efficiently in a short period of time. As roselle is harvested in December, during the dry and scarce raining winter season, solar systems can be used. In this paper two prototypes were developed, and both used electric power provided by solar panels to turn on fans. The hot air convective tray dryer also used electrical resistance.

Materials and Methods

Roselle calyxes were grown and dried at Loma Bonita, Guerrero, Mexico, (17°25´47” N, -101°11´19” W, 17 m ASL). Relative humidity during harvest was over 60%, so dehydration was slow. Roselle var. “Tecoanapa” was harvested the previous day at 19:00 and gathered in bags during the night avoiding calyx dehydration before drying. Maximum solar radiation collected by the tunnels was obtained at an inclination angle of 22° with respect to the floor. Two different prototypes were built and tested: a solar tunnel type drier (Figure 1) and a hot air recirculated tray furnace.

Prototypes

The solar tunnel drier was 3.00 m long, 1 m wide and 1.10 m high and presents a polyethylene plastic cover. The transparent cover presents a transmission varying from 75 to 85%. The 3 m long x 0.9 m wide tray presents a galvanized sieve with 0.01 m square grids. The air was extracted from the tunnel using two extractors at a speed of 0.15 m/s (model 4715FS-12T-B50, 115 V@ 0.19 A) after passing through the calyxes. RH data was acquired every five minutes using a relative humidity sensor (mod TRH-303, RIXEN) and the smalls fans were turned off/on every 15 minutes during the day. The incoming solar radiation was measured with a silicon pyranometer (mod CS300, Campbell Scientific, Loughborough, UK). A 60-watt solar panel charged a 12-volt car battery, and an inverter (model INCO-200, Trouper, Mexico) provided the 115 V required. (figure1,2). The hot air convective drier was built with galvanized sheets and with trays having a 5x5 mm stainless steel sieve (Figure 2). The patented hot air convective dryer [17] presents a chamber, centrifugal fans, and a plurality of trays where the food product is dried. It is 3 m long, 1 m wide and 1 m high, and uses 15 trays for drying. In the rear area of the chamber a concave deflector redirects the air flow homogeneously in the opposite direction towards the different trays. All the chamber skeleton presents a heat-isolator material that avoids heat transfer from and to the environment. A centrifugal fan recirculates the hot air again to the internal air conduction duct, where two 450 W resistances heat the air. A temperature controller (mod E5CB, OMRON, USA) with a J-type thermocouple sensor powers the resistances with the help of a power relay. A 1500-watt solar panel charged a 12-volt battery group. A power inverter (model BEL1500XT, BELTTT, Hong Kong) provided the 220VAC source energy. A relative humidity sensor (model N322RHT, Novus, Brazil) monitored air RH within the drying chamber.

Figure 2: Hot air convective chamber with solar panels, fans, recirculating duct, trays and resistance.

Experimental Setup

The fans within the solar drier were turned-on and turned off during the day in symmetrical periods. Therefore, fans operated 20 times for fifteen-minute periods throughout the day. At night, condensation occurred, and drops fell on the tray. Calyxes were removed and placed in a dry covered place avoiding them acquiring moisture again. A group of 20 calyxes were weighted every half hour with a precision balance (model PX3202/E, OHAUS, Germany) determining it weight to obtain its water loss. The precision balance has a readability of 0.02 g and a linearity of ±0.2 g. Minimum weight that can be measured corresponds to 7.2 g and 20 dried calices at 12%db will exceed this value. Calyx moisture Mi was obtained by equation 1, where wi represents its weight in whichever moment and wf is the final weight after being dried in a laboratory stove for 24 hours.

Fifteen trays were placed within the oven, and final calyx moisture was measured in the middle and top tray throughout all its area. To study final drying homogeneity, the tray area was divided in 5 x 5 cm areas. The calyces within the area were weighted, packed in a paper numbered bag, and taken to the stove for obtaining final organic matter and its weight, wf. In the solar drier 200 bags were taken for analysis, meanwhile in the hot air tray drier only 100 bags per tray were collected. In another experiment weights of 20 calyces were obtained every half an hour to determine their drying curve. Five J-thermocouples were distributed at different heights within the chamber and connected to a homemade ESP32 datalogger.

Results

Solar Indirect Drier

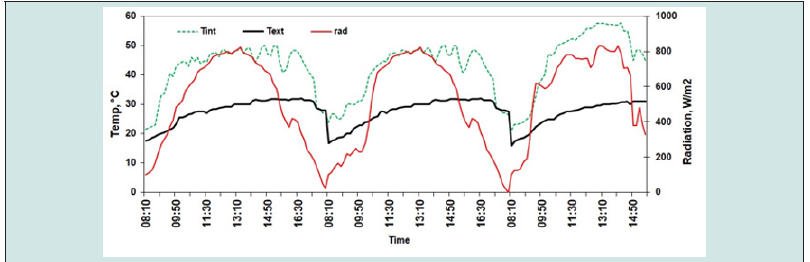

Figure 3: Roselle solar drying showing solar radiation, internal and external temperatures during the three days.

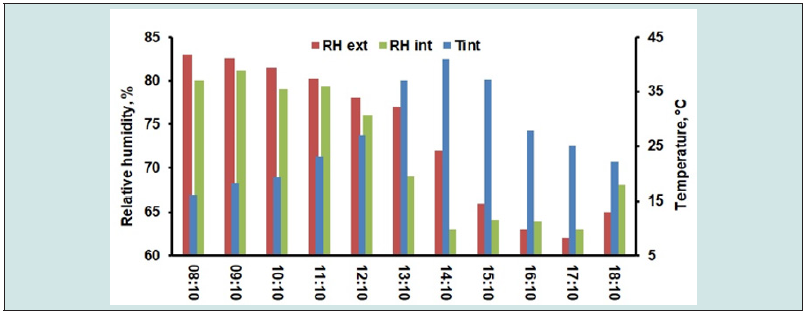

Air external temperature increased everyday up to 17:00, dropping quickly as sea-wind entered after sunset, Figure 3. The drier internal temperature remained steady over 43°C from 10:00 until 17:00; On the third day the temperature inside the drier increased over 50°C. The green line temperature peaks, in figure 3, are caused by fan intermittent operation. Solar radiation over 600 Wm-2 lasted only 3 hours. Relative proximity to the sea and sea breeze increased air relative humidity to values above 60% throughout all day, Figure 4. Relative humidity inside the drier was 2 or 3% less than outside RH. Only at 13:00 and 14:10 the difference between the internal and external RH was over 10%, as the air temperature increased, and the fans were turned off. Roselle calyxes were dried until their moisture was 13% taking 25 hours. External temperature increased from 21°C in the morning up to 45°C in the afternoon, and its peak radiation was found after midday, (Figure 3-5).

Tray Drier

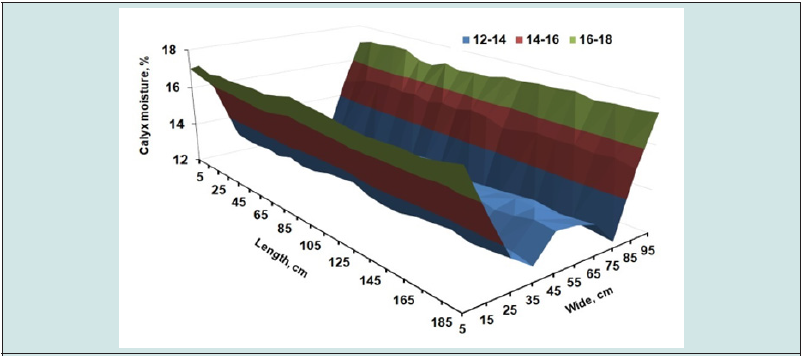

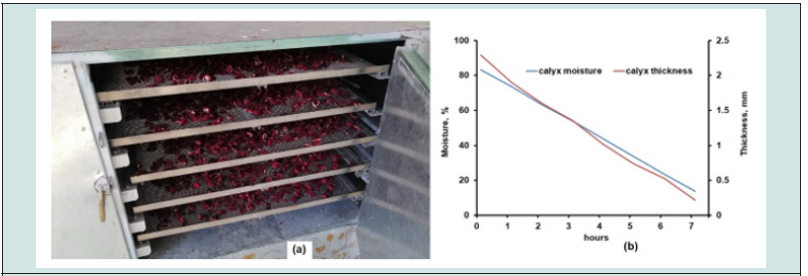

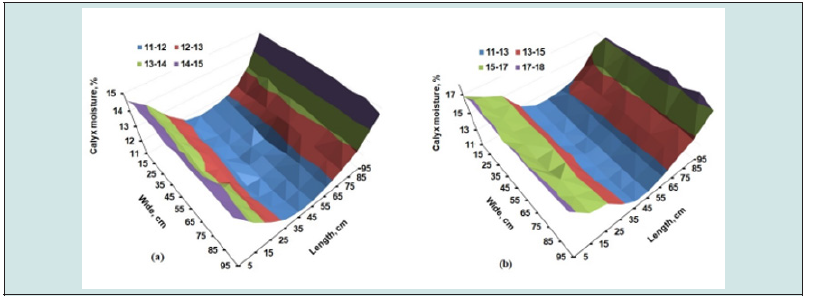

Hot air circulated continuously within the tray drier and removed moisture by forced convection from the calyces placed in trays, Figure 6a. The hot air heated by the electrical resistances was circulated by two fans at 2 ms-1. A turbulent flow was generated as the air hit the extreme end door section reducing the thickness of the air boundary layer. As calyx water evaporates, it diffuses from the internal cells by the capillary action. In the tray drier, calyxes were dehydrated in a period of 7 hours at 55°C, and in 12 hours at 40°C. As calyces dried up, its thickness decreased from 2.3 mm@84% to 0.28 mm@12.8%, Figure 6b. As surface curves show drier calyces were found in the center (blue) as airflow is higher, Figure 7. Minimum calyx moisture ranged between 11.2-11.7%, increasing to 14.5% in the side close to the door, in the central tray, Figure 7a. In the top tray maximum final moisture of 17.3 % was found in the edges, being the lower of 12.2% in the center, Figure 7b. Calyxes remained wetter at the top and bottom trays. (Figure 6a-Figure 7b).

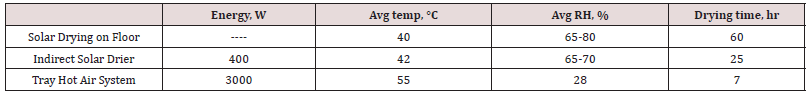

Discussion

In a similar comparison with mango slices in Thailand it was found that the drying time in the hot-air tray drier at 70°C was of one hour, meanwhile a greenhouse solar drier employed 2 hours in the process [11]. Fruit final moisture was 12.4% and solar radiation during the drying period was over 900 Wm-2. Hot air temperature within the convective drier was constant throughout the process, differing with the temperature changes found within the solar drier which is dependent on incoming solar radiation; solar radiation was only 3 hours over 600 Wm-2 and never achieved 1000 Wm-2. As air temperature increases, its RH decreases [11]. Fans removed the air continuously, so the air temperature within the tunnel and applied to the calyces was not optimum. If fans can have longer off periods than on periods or air recirculation can take place the drying time will be reduced. It is important to note that in the electrical tray drier, air relative humidity decreased from 90% to 29% after 15 minutes when a rainy environment was found in July. This air moisture remained constant throughout the process under mango drying with the same tray oven. Energy must be considered as an important parameter for determining the best drier option. When calices are dried over a black painted structure without fans, there is no energy consumption, but drying takes a longer time, Table 1. The hot air drier required 3000 W for the resistance and fan consumption. When comparing both roselle driers, it is important to consider their effect within calyces’ antioxidants such as anthocyanin, flavonoids [18-19], and phenols. Tray drying with hot air and high fan velocity affects tissue structure, deforming cell wall [18]. Catechin loss was 6% higher in a heat pump drier than in a solar drier and vitamin C remained higher in the solar drier [20]. (Table 1).

Table 1:Energy consumption, drying time average relative humidity and temperature obtained for each system.

Conclusion

After drying roselle calyxes with both prototypes the following conclusions were obtained. A drying time of 7 hours was achieved at a controlled temperature of 55°C in the tray drier. As hot air is recirculated, air relative humidity remains low resulting in an excellent dried product. Although the employed energy was over 3000 watts it was provided by a solar panel inverter suite. The solar indirect drier only passed the environmental air through the tunnel and air temperature only increased by 10°C, meanwhile relative humidity was always high. The 40°C-high moisture air dried the calyces for 25 hours. Both driers presented lower final calyx moisture at the tray central zones, being higher in the extremes.

Acknowledgements

I would like to acknowledge DGIP who funded this project.

References

- Technical Platform on the Measurement and Reduction of Food Loss and Waste. Food and Agriculture Organization of the United Nations.

- Melikoglu M (2020) Reutilisation of food wastes for generating fuels and value added products: A global review. Environ Technol Innov 19: 101040.

- Ramesh N, Paschapure M, Nippanikar N, Karigoudar S, Nataraj SJR, et al. (2016) Performance studies of sustainable solar dryer for drying agricultural products. Indian Journal of Science and Technology 9(45): 1-9.

- Chichango F, Cristóvão L, Muguirima P, Grande S (2023) Solar dryer technologies for agricultural products in Mozambique: An overview. Research Society and Development 12(4).

- Chaatouf D, Salhi M, Raillani B, Amraqui S, Mezrhab A (2021) Assessment of a heat storage system within an indirect solar dryer to improve the efficiency and the dynamic behavior. Journal of Energy Storage 41: 102874.

- Shimpy KM, Kumar A (2023) Designs, Performance and Economic Feasibility of Domestic Solar Dryers. Food Eng Rev 15: 156-186.

- Mohana Y, Mohanapriya R, Anukiruthika T, Yoha KS, Moses JA, et al. (2020) Solar dryers for food applications: Concepts, designs, and recent advances. Sol Energy 208: 321-344.

- Gorjian S, Hosseingholilou B, Jathar LD, Samadi H, Samanta S, et al. (2021) Recent Advancements in Technical Design and Thermal Performance Enhancement of Solar Greenhouse Dryers. Sustainability 13(13): 1-32.

- Taşeri L, Gülcü M, Aktaş T (2023) Comparison of Grape Pomace Drying Using a Solar Dryer and Under Open Sun Conditions. Viticulture Studies 3(1): 31-40.

- Essalhi H, Benchrifa M, Tadili R, Bargach M (2018) Experimental and theoretical analysis of drying grapes under an indirect solar dryer and in open sun. Innovative Food Science & Emerging Technologies 49: 58-64.

- Kingphadung K, Kurdkaew P, Siriwongwilaichat P, Kwonpongsagoon S (2022) Comparison of Performance and Economic Efficiency for Greenhouse Solar versus Hot Air Drying: A Case of Crispy Mango Production. Processes 10: 311.

- Behera DD, Mohanty RC, Mohanty AM (2023) Thermal performance of a hybrid solardryer through experimental and CFD investigation. Journal of Food Process Engineering 46(8): e14386.

- Singh P, Gaur MK (2021a) Environmental and economic analysis of novel hybrid active greenhouse solar dryer with evacuated tube solar collector. Sustainable Energy Technologies and Assessments 47(101428): 1-10.

- Waskale H, Bhote S, Bhong M (2017) Effect of Air Recirculation in the Energy Saving During Drying Process of Fruits, Vegetables and Grains: A Review. International Journal on Theoretical and Applied Research in Mechanical Engineering 6: 2319-3182.

- Phong NT, Duc LA, Khuyen ND (2023) Effects of drying methods and drying temperature on product quality of Phyllanthus Amarus (P. Amarus). IOP Conference Series Earth and Environmental Science 1155(1): 012013.

- Misha S, Mat S, Ruslan MH, Sopian K, Salleh E (2013) Review on the application of a tray dryer system for agricultural products. World Applied Sciences Journal 22(3): 424-433.

- Hahn F (2023) Fruit dehydrator by forced convection and air recirculation. [Deshidratador de frutos con convección forzada y recirculación de aire]. Patent in process.

- Juhari NH, Martens HJ, Petersen MA (2021) Changes in Physicochemical Properties and Volatile Compounds of Roselle (Hibiscus sabdariffa L.) Calyx during Different Drying Methods. Molecules 26(20): 6260.

- Ibrahim R, Mazuki NAF (2013) The quality of roselle (Hibiscus sabdariffa L.) juices made from roselle calyces stored at different cold temperatures. Malays Appl Biol 42(1): 67-71.

- Tajudin N, Tasirin S, Ang WL, Irwan M, Lim L (2019) Comparison of Drying Kinetics and Product Quality from Convective Heat Pump and Solar Drying of Roselle Calyx. Food and Bioproducts Processing, 118: 40-49.

Top Editors

-

Mark E Smith

Bio chemistry

University of Texas Medical Branch, USA -

Lawrence A Presley

Department of Criminal Justice

Liberty University, USA -

Thomas W Miller

Department of Psychiatry

University of Kentucky, USA -

Gjumrakch Aliev

Department of Medicine

Gally International Biomedical Research & Consulting LLC, USA -

Christopher Bryant

Department of Urbanisation and Agricultural

Montreal university, USA -

Robert William Frare

Oral & Maxillofacial Pathology

New York University, USA -

Rudolph Modesto Navari

Gastroenterology and Hepatology

University of Alabama, UK -

Andrew Hague

Department of Medicine

Universities of Bradford, UK -

George Gregory Buttigieg

Maltese College of Obstetrics and Gynaecology, Europe -

Chen-Hsiung Yeh

Oncology

Circulogene Theranostics, England -

.png)

Emilio Bucio-Carrillo

Radiation Chemistry

National University of Mexico, USA -

.jpg)

Casey J Grenier

Analytical Chemistry

Wentworth Institute of Technology, USA -

Hany Atalah

Minimally Invasive Surgery

Mercer University school of Medicine, USA -

Abu-Hussein Muhamad

Pediatric Dentistry

University of Athens , Greece

The annual scholar awards from Lupine Publishers honor a selected number Read More...